In "Comparative Study of the Shear Test Results of a Cable Bolt on Three Laboratory Test Apparatuses," researchers delved deeply into the crucial role of cable bolts in rock reinforcement and provided a more profound understanding of their shear performance by comparing different laboratory test methods. This study aimed to evaluate and optimize the design and application of cable bolts to ensure safety and efficacy in geotechnical engineering.

Comparison of Experimental Methods

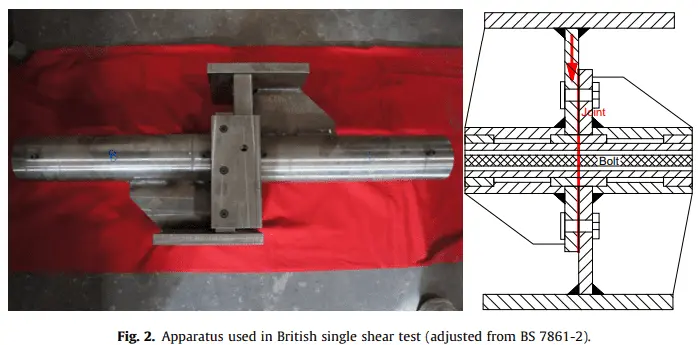

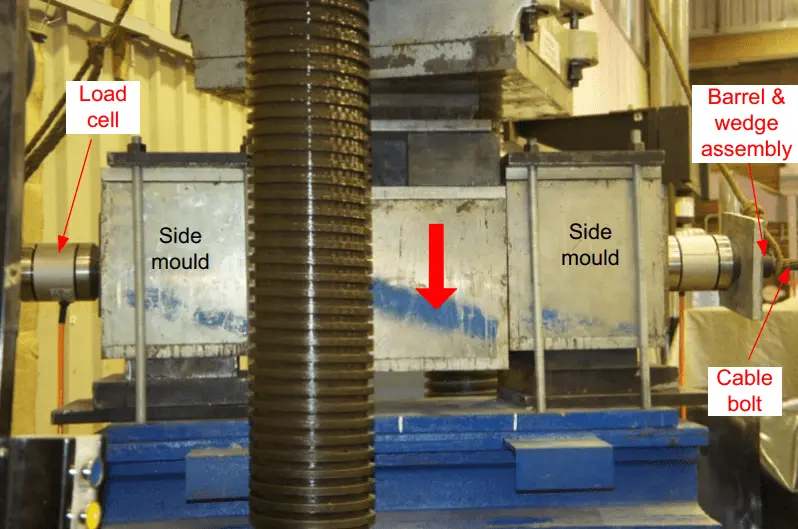

The article first introduces three different laboratory test setups: the British Standard Single Shear Test (BSST), the Megabolt Single Shear Test (MSST), and a device developed by the University of Wollongong. Each method has its unique testing configuration and parameters, designed to simulate the reaction of cable bolts to shear forces in rock. The BSST method is relatively simple and primarily used for preliminary evaluations. At the same time, the MSST and the University of Wollongong's apparatus provide more complex and comprehensive testing environments to simulate actual rock conditions.

Analysis of Experimental Results

By comparing the test results from the three methods, researchers found that despite variations in specific values, the methods showed a degree of consistency in assessing bolt performance. This suggests that laboratory testing is an effective way to predict cable bolts' performance under actual conditions. However, significant differences also exist, indicating the need to consider more variables and conditions in real-world applications.

Discussion on Influencing Factors

In an in-depth discussion of factors affecting the shear performance of cable bolts, the study revealed several key factors, including joint friction, bolt debonding, boundary conditions, bolt installation angle, and the contact conditions between the bolt and the steel mold.

Joint Friction is one of the key sources of force in the shear process. The interaction between the bent bolt and the rock mass alters the normal force on the shear joint, while the change in the joint friction coefficient reflects the damage to the rock mass and the crushing of the rock around the bolt.

Bolt Debonding occurs when the bond between the bolt and the encapsulating material weakens, causing the bolt to move or rotate axially under load. The degree of bolt debonding will affect the shear stiffness and shear strength of the entire shear system.

Boundary Conditions include the normal and radial constraints of the bolt system. These conditions are usually fixed in laboratory settings but may vary on-site, affecting the actual performance of the bolt.

Bolt Installation Angle adjustments are necessary to simulate actual rock conditions, but for most existing shear test devices, this is impossible. Different installation angles affect how the bolt contacts the rock mass, thereby impacting its performance.

Contact Conditions between the Bolt and Steel Mold are also important in the shear process. Theoretically, the bolt only contacts the encapsulating material and rock mass before final failure. Any unexpected contact between the bolt and the steel frame may lead to severe stress concentration and early failure of the bolt.

By analyzing these factors, the research emphasizes the importance of considering these factors in laboratory testing and field application to ensure the performance and safety of the bolts.

Significance for Practical Application

The article discusses how to apply these laboratory test results to actual rock reinforcement engineering. Researchers note that while laboratory conditions can provide detailed data and control, the rock conditions on-site are often more complex and variable. Therefore, engineers need to integrate laboratory test results with actual site conditions when selecting and evaluating anchoring systems.

Conclusion

The study shows that appropriate laboratory tests can provide important predictive information for the performance of cable bolts. Different test methods have their advantages and limitations, but by comparing and understanding these methods, the design and application of cable bolts can be more accurately assessed and optimized. The research also emphasizes the importance of continuing research and developing more advanced testing methods and technologies to ensure the safety and efficacy of underground engineering.

Overall, this article offers profound insights and valuable guidance for enhancing the safety and efficiency of geotechnical engineering and optimizing the design and application of cable bolts. By understanding and addressing various influencing factors, we can better design and evaluate rock anchoring systems, ensuring the stability and safety of underground structures.